CE Certification Discount Coal Mill Resistant Castings Suppliers - Travelling Grates&Chain Grate&wear plate on Grate-kiln – Xingtejia

CE Certification Discount Coal Mill Resistant Castings Suppliers - Travelling Grates&Chain Grate&wear plate on Grate-kiln – Xingtejia Detail:

As We have supplied many pellet plants for many years, our casting and machining processes have been very mature. In recent years, almost no customer complaints have been received. If you have any demand, please contact our team. We will give you professional solution.

The material we use on these parts are usually heat resistant steels. Heat resistant is the material with high strength and stability used at high temperature. It is often used in industries and fields such as metallurgy, heat treatment, cement, power plants and so on. According to different applications, this kind of material needs to have good toughness, weldability and microstructure stability in addition to high temperature strength and resistance to high temperature oxidation corrosion.

(1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 2 |

19 – 22 |

max 0.04 |

max 0.03 |

24 – 27 |

max 0.5 |

Chemical composition % of steel GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 – 1.4 |

1 – 2.5 |

0.5 – 1 |

max 1 |

max 0.035 |

max 0.03 |

27 – 30 |

max 0.5 |

Our advantage

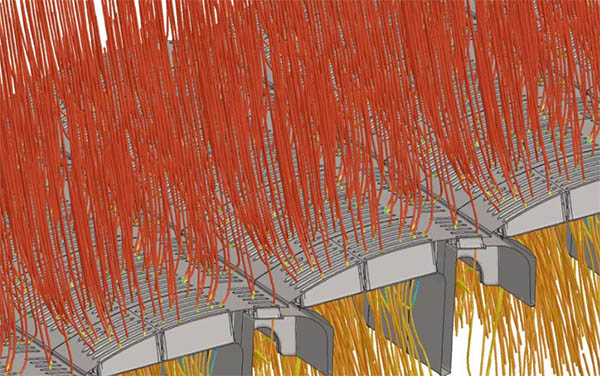

1. We use shell mold precision casting. Products manufactured by us always have good quality and almost no casting defects.

2. We have produced wear parts for pellet plants for many years. We have rich experience on doing it.

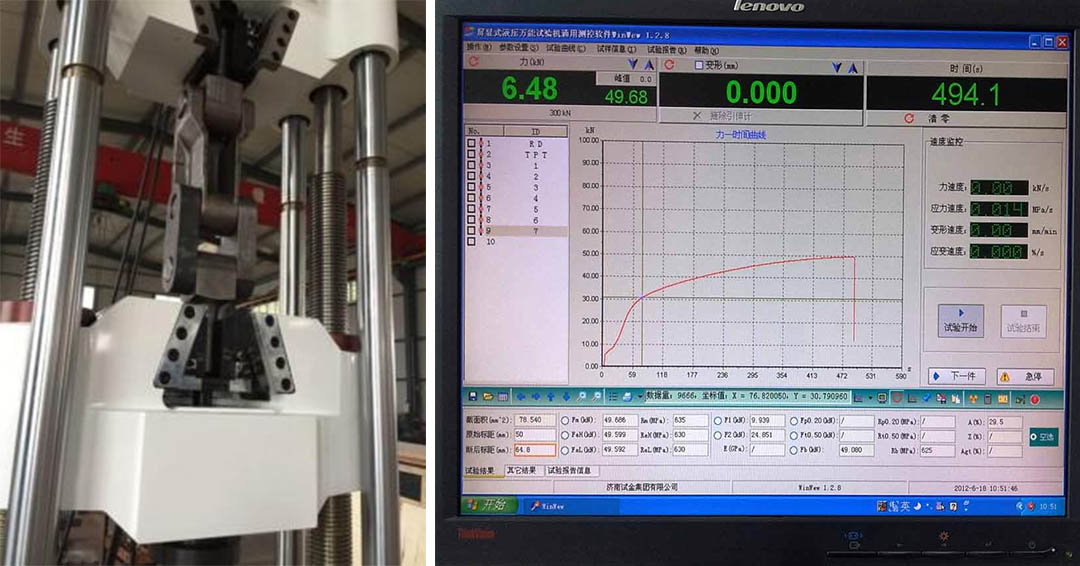

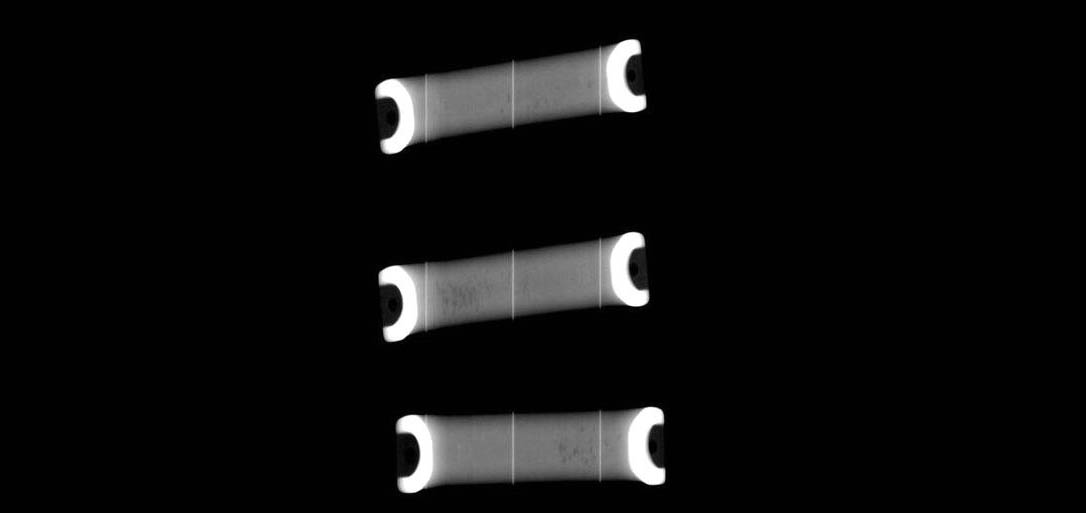

3. We have complete inspection equipment.

200 tons’ tensile testing machine to test the mechanical property of the Chain Grate

RT Equipment to test the Internal defects in the castings.

For more inquiries or technical questions, please contact XTJ Service Team. We will provide the most reasonable technical solution and the best quotation according to your product.

Wear is a complex field and there are numerous types of wear.

Different types (and combinations) of wear mechanisms requires different approaches to the material selection and design.

Abrasive Wear – occurs when a hard-rough surface slides across a softer surface. Generally, to reduce abrasive wear you need a harder material. Applications include chutes and feed hoppers which see sliding wear.

Erosive Wear – occurs when particles impact the wear surface. As well the gradual removal of material from cutting and gouging actions, the kinetic energy of the impacting particles in can cause surface work hardening and micro cracking which can result in delamination and spalling. Consideration of material-toughness as well material-hardness as well as plant design e.g. particle Impingement Angle and Velocity are important to controll erosive wear. Applications include pneumatic and hydro conveying, grizzlies, screens, and cyclones.

Corrosive Wear -This kind of wear is a mixture of corrosion & wear. The mechanical wear can be significantly increased by chemical reaction between the worn material and the corroding medium in the application environment, e.g. Paddle Mixers in Super Phosphate Production. Material Selection is very important to optimise the corrosion-wear properties of the component.

XTJ Manufacturing Specialise in the manufacture of wear resistant metal components to meet the arduous conditions in Quarrying and mining Industries.

Our team of Metallurgists and Mechanical Engineers will work closely with you to ensure we understand your requirements and meet you needs at globally competitive pricing.

We offer a range of Wear resistant casting materials and full heat treatment capability to optimise material properties to meet your requirements.

Well Packed Travelling grate

Well finished grates

Chain grate assembly inspection

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for CE Certification Discount Coal Mill Resistant Castings Suppliers - Travelling Grates&Chain Grate&wear plate on Grate-kiln – Xingtejia , The product will supply to all over the world, such as: Nigeria, Austria, Cyprus, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!