Our team of Metallurgists and Engineers will ensure you have complete confidence the product supplied.

Our inspection and testing laboratories provide Metallographic, Mechanical, Dimensional, Chemical testing, and so on .

We will tailor an Inspection and testing regime to meet your requirements. Our Quality Plans range from routine testing to fully documented verification and traceability.

We offer a complete suite of Destructive and Non Destructive testing including:

1. Co-Ordinate Measuring Machine CMM

2. Radiography

3. Magnetic Particle Inspection

4. Die Penetrant Inspection

5. Spectrographic Chemical Analysis

6. Tensile Testing

7. Compression Testing

8. Bend Testing

9. Hardness Testing

10. Metallography

Chemical Composition Analysis

After raw materials are melted into molten steel. We use spectrometer to test the material of molten steel before casting to make sure the products have the accurate steel grade.

Dimension Inspection

Dimension inspection is based on the drawing to measure whether the casting dimension is within the tolerance range, so as to find the error of shape and dimension. In addition, the accuracy of machining datum position, distribution of machining allowance and wall thickness deviation should be carefully checked.

Magnetic Particle Inspection(MPI)

MPI is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC) (rectified AC).

Ultrasonic Testing (UT)

UT is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion.

Hardness Test

Hardness is the ability of materials to resist the pressure of harder objects into their surfaces. According to the different test methods and the range of adaptability, the hardness units can be divided into Brinell hardness, Vickers hardness, Rockwell hardness, micro Vickers hardness, etc. different units have different test methods, which are suitable for different materials or occasions with different characteristics.

Radiographic Testing(RT)

(RT or X-ray or Gamma ray) is a non-destructive testing (NDT) method that examines the volume of a specimen. Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in your operation.

Mechanical Property Test

Our company is equipped with 200 tons and 10 tons tensile machine. It can be used to test the mechanical properties of some special products.

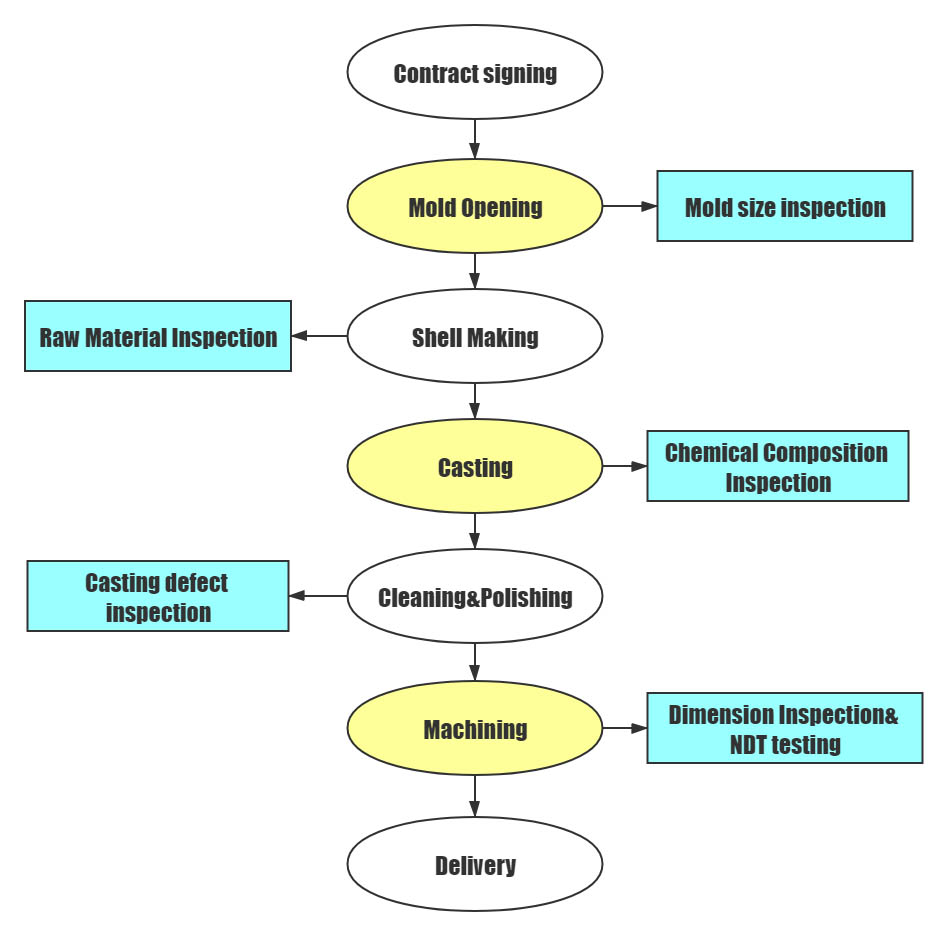

Inspection Flow Chart

High quality, zero defect is the goal we always pursue. The affirmation of customers is the driving force for our continuous progress. After experiencing more than a decade of international trade, we have made a significant improvement in the quality control of castings. In recent years, we have increased a lot of advanced testing equipment such as 200/10 Tons Tensile testing machine, Ultrasonic testing equipment, Magnetic particle testing equipment, X-ray flaw detection equipment, Two chemical composition analyzers, Rockwell hardness tester and so on.