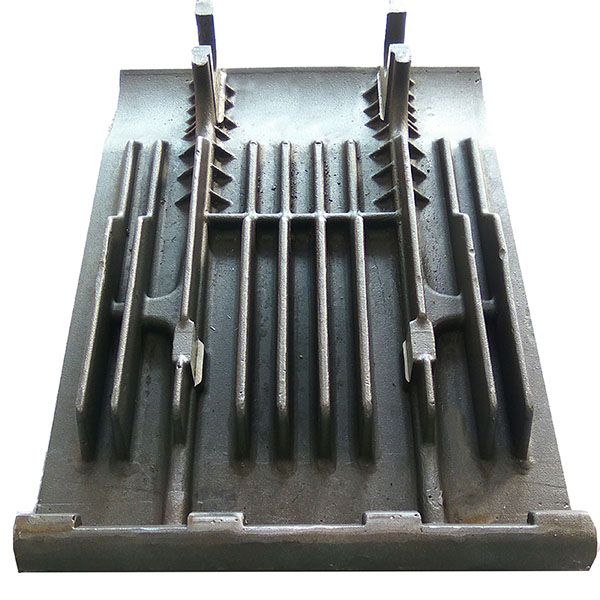

High Quality OEM Grate Plate Factories - Trash incineration Furnace grate Stove grate – Xingtejia

High Quality OEM Grate Plate Factories - Trash incineration Furnace grate Stove grate – Xingtejia Detail:

Heat resistant castings are typically made out of stainless steels that have a high Chromium and Nickel count. Castings made out of heat resistant alloys are excellent for components exposed to dry gases at high temperatures for long periods of time. Industries that benefit from heat resistant castings include Energy, Engines, Furnaces/Ovens, and Petrochemical.

Heat resistant steel castings are also referred to as oxidation resistant steel castings, refractory steel castings, heat resistant stainless steel castings.

Heat resistant steel is a kind of alloy steel that has higher mechanical strength and better chemical stability at high temperatures.

Heat resistant steel castings have been used to make heat resistant components in industrial furnace, heat exchanger, thermal treatment furnace, grate cooler and other heat resistant industrial equipments.

The standard ASTM A297 covers iron-chromium and iron-chromium-nickel alloy castings for heat-resistant service, the grades covered by ASTM A297 are general purpose alloys and no attempt has been made to include heat-resisting alloys used for special production application.

XTJ proudly offer heat resistant steel castings that fully meet the ASTM A297 standard, including:

• ASTM A297 Grade HF, Type 19Cr-9Ni

• ASTM A297 Grade HH, Type 25Cr-12Ni

• ASTM A297 Grade HI, Type 28Cr-15Ni

• ASTM A297 Grade HK, Type 25Cr-20Ni

• ASTM A297 Grade HE, Type 29Cr-9Ni

• ASTM A297 Grade HU, Type 19Cr-39Ni

• ASTM A297 Grade HW, Type 12Cr-60Ni

• ASTM A297 Grade HX, Type 17Cr-66Ni

• ASTM A297 Grade HC, Type 28Cr

• ASTM A297 Grade HD, Type 28Cr-5Ni

• ASTM A297 Grade HL, Type 29Cr-20Ni

• ASTM A297 Grade HN, Type 20Cr-25Ni

• ASTM A297 Grade HP, Type 26Cr-35Ni

Available casting methods for heat resistant steel castings

1. Shell Mold Precision casting

2. Investment casting

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for High Quality OEM Grate Plate Factories - Trash incineration Furnace grate Stove grate – Xingtejia , The product will supply to all over the world, such as: Bangkok, Plymouth, Colombia, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.